TECNOSPAZIO TECHNOLOGY

ALIAS

SEQUENTIAL MATHEMATICAL MODELS

OF THE OPERATIONS

FROM RAW MATERIALS

TO END PRODUCTS

ABLE TO AUTOMATICALLY ADAPT

TO REAL MEASURES

OF THE RAW MATERIALS USED

TECHNOLOGY

APPLIED TO ALIAS

TECHNOSPACE SYSTEM ABILITY

TO AUTOMATICALLY SELECT

THE BEST CONFIGURATION

(MATERIAL/ MACHINERY/ METHOD/ TOOL/

CUTTING PARAMETERS)

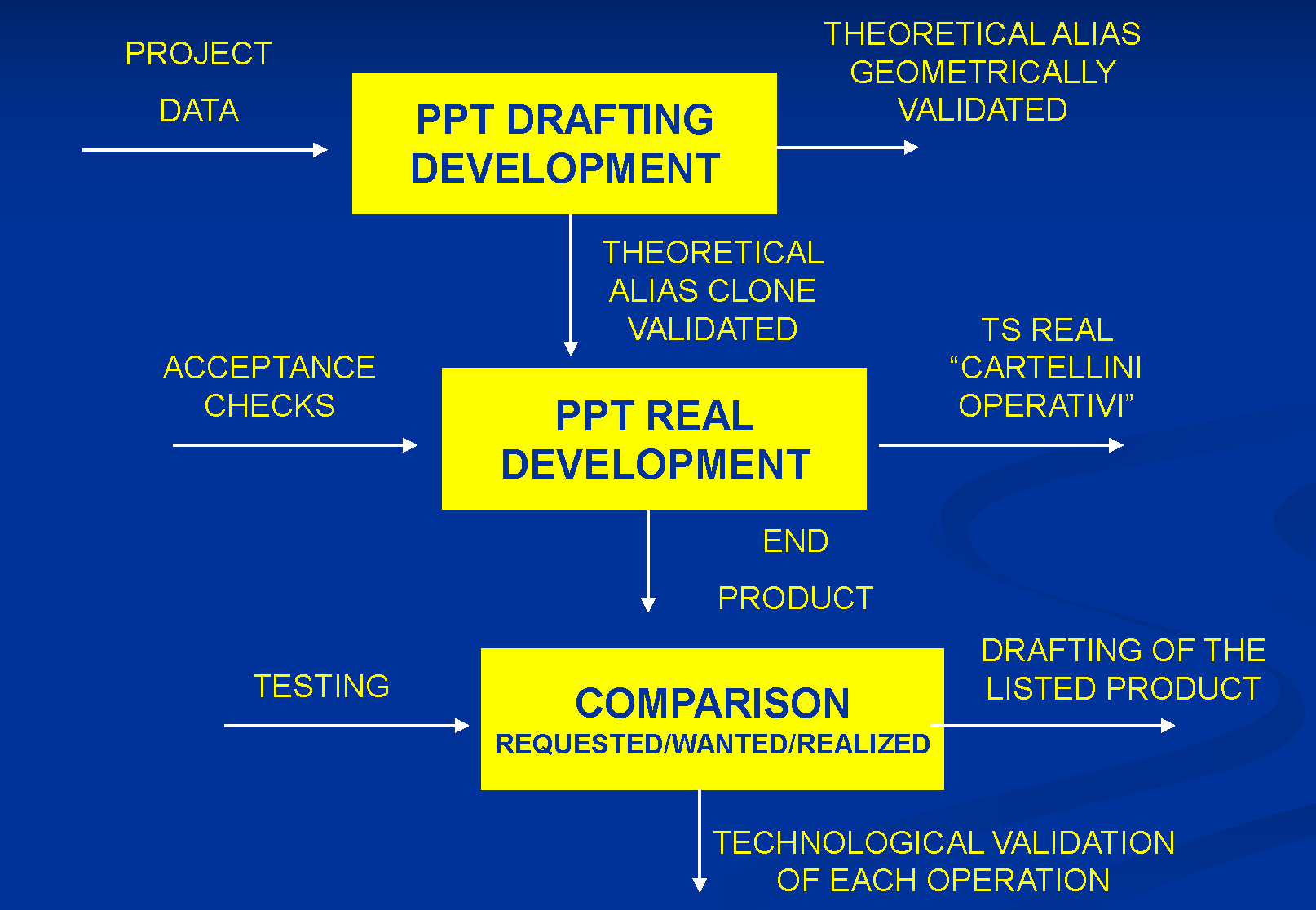

PPT

THE PART PROGRAM TECHNOSPACE

IS THE RESULT OF A TECHNOLOGY

PRODUCED BY TECHNOSPACE

TO AUTOMATICALLY GENERATE

PART PROGRAMS

EQUIPPED WITH DIAGNOSTICS TO AVOID ERRORS

THAT VERICUT DOES NOT VERIFY

(I.E. GEOMETRICAL AND NON-GEOMETRICAL ERRORS)

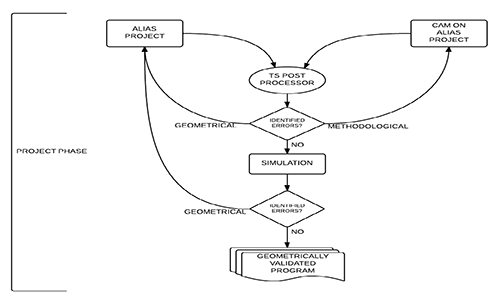

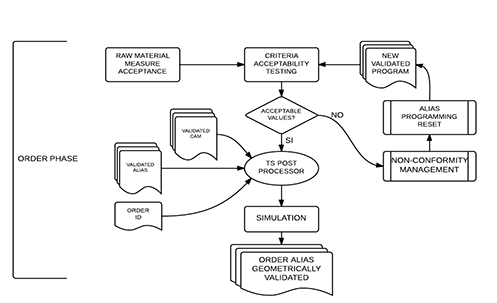

TS DIAGNOSTICS

VERICUT identifies

Many geometrical errors through the simulation of tool paths with models of:

– Raw material operations

– Equipment

– Machinery head

– Tools

Many program errors by comparing:

– VERICUT output model

– The end model of the operation

TS POST PROCESSOR identifies

GEOMETRICAL errors that Vericut does not manage:

– Drilling tools sequences

– Interchanges management and rapprochement of twin gearchanges

TECHNOLOGICAL errors that Vericut does not manage:

– Tool life depending on the path

– Residual life management and optimization